Aalto University - ARTS 3D Printing

Material Jetting (Polyjet Printing)

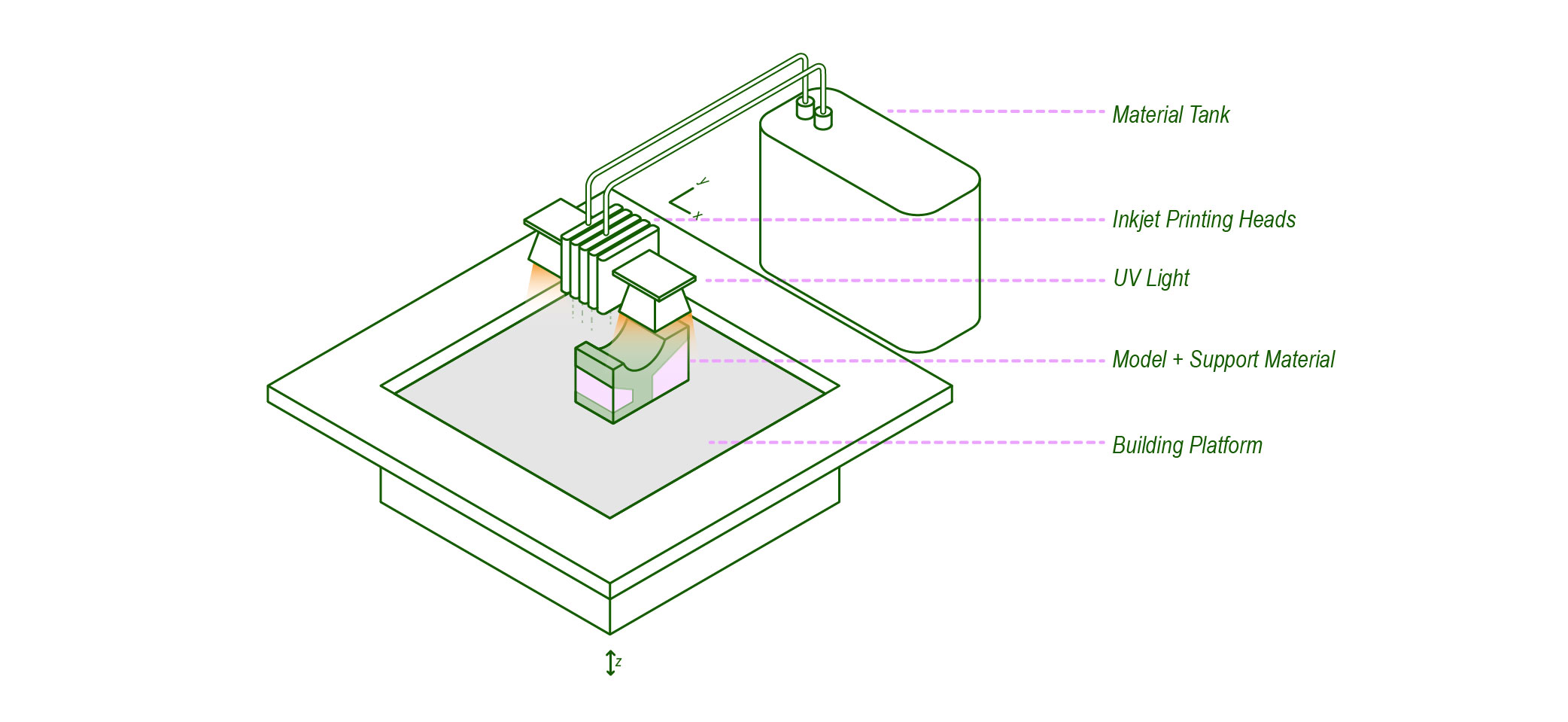

Polyjet printers, such as the one we have at the workshop, works in the same fashion as a 2D standard inkjet printer (i.e. an Epson or HP printer). However, instead of printing just one layer of ink over paper, it prints multiple layers, one over the other, of a photo reactive resin material to create a three-dimensional object.

These type of machines generally are equipped with multiple print heads that will jet small droplets of the material into a platform, and then exposed to a UV light, where the material solidifies. After every layer, the platform moves down and the process repeats.

In the same way inkjet printers are capable of printing and mixing multiple colors in the same paper, the polyjet machines are able to print multiple materials at the time, making it one of the only 3D printing processes that is capable of this.

Polyjet prints are highly accurate in dimension, and have a very smooth surface, making them suitable for final prototypes, as well as realistic pieces. Some machines are even capable of printing in color, which makes this type of technology is widely used in research and development units, where it is relevant to visualize the color, material and finish of developing products. On the downside, due to the type of resin used, this is one of the most expensive 3D printing processes. The material also degrades easily when exposed to sunlight and UV light.

Characteristics of Material Jetting prints

- Are highly detailed and one of the most accurate 3d printing technologies to date (High dimension tolerance of +/- 0.1mm).

- The surface tends to be very smooth, and depending on the machine it can be shiny or opaque.

- Objects are directly built on the printing platform, and always require a support structure that will hold them – independently of their geometry, the angle, or if they are interior or exterior. This support is printed in a water-soluble soft material that can be mechanically removed after the print is done, leaving no support marks.

- Prints are completely solid. In addition, each print collects a reasonable amount of “waste material” which is necessary for the printer to purge the printing heads. This leads to using more material than with other technologies.

- White resin (VeroWhite): It is a rigid opaque material.

- Rubber-Like resin: Flexible. It simulates thermoplastic elastometers. It is possible to modify its shore hardness when combined with rigid resin. It is prone to tearing, therefore, not suitable for functional parts.

- Support: Soft material easy to remove mechanically or with a pressure washer.